Digital storage system for RFID technology

Traditional digital operation in the warehouse

-------------------------------------------------------------------------------

● static inventory management is mainly used

Manual operation mode of the ● job document

The real-time monitoring of ● storage operation is not in place, and the errors cannot be corrected in time

System Overview

----------------------------------------

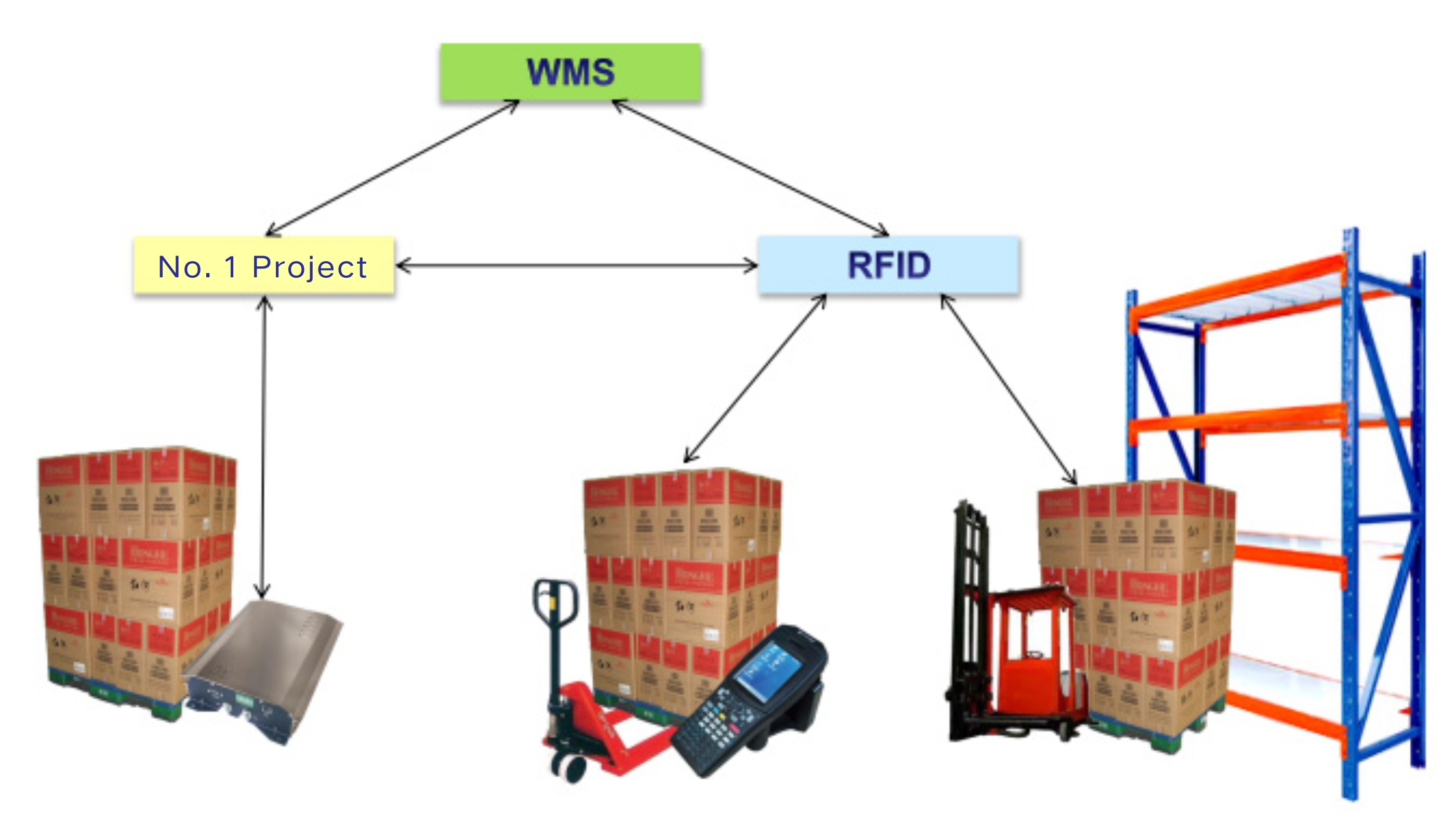

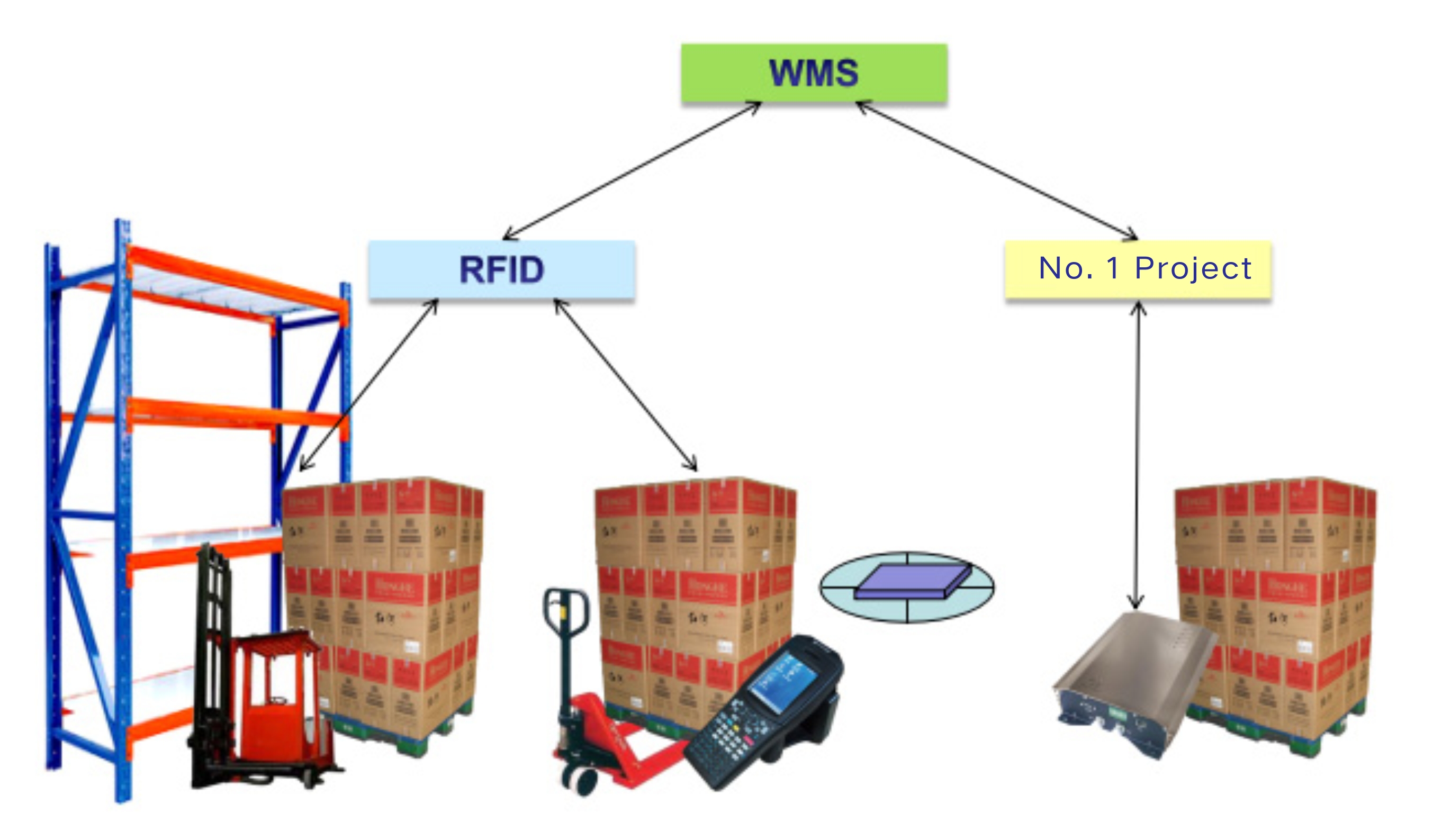

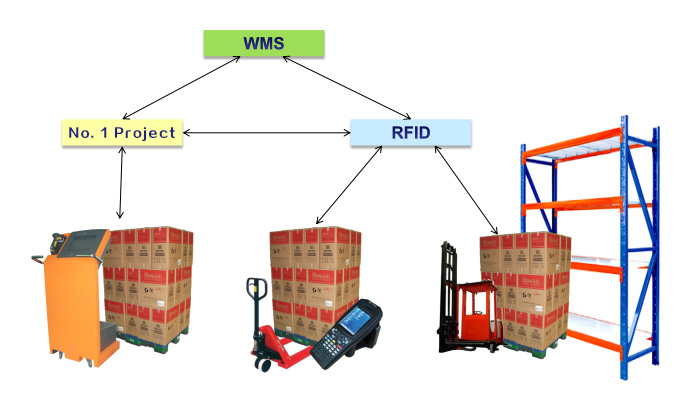

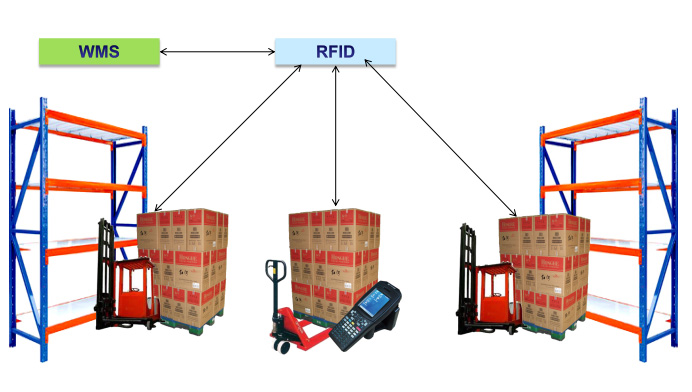

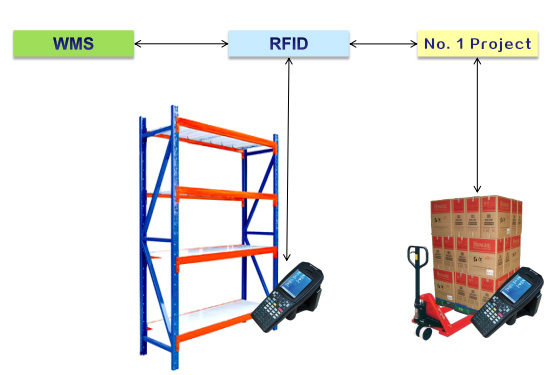

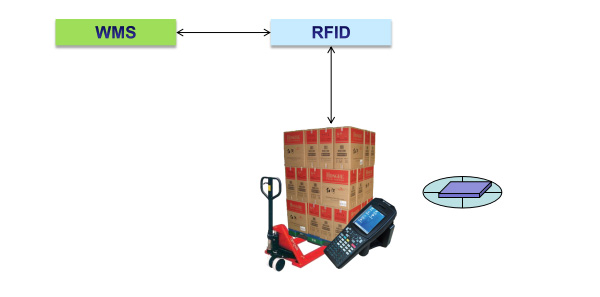

The RFID-based warehouse operation system realizes the two-way connection between vehicle guidance and task management and warehouse storage operation management outside the warehouse, Warehousing management (WMS) and " No.1 Project " seamlessly combine with data synchronization, efficient entry and exit operation, cargo location allocation and management strategy, data base of library operation task assignment and management with decision-making support, storage operation process tracking, automatic trace, cargo location operation flexible, accurate and error correction, Traceability of the tray information adjustment, And the cargo space pallet inventory is simple and efficient, Wait, Thus, it truly realized the warehousing and logistics on the basis of digital management, Realize a high degree of unity between physical flow, job flow and information flow.

RFID Technical Introduction

------------------------------------------

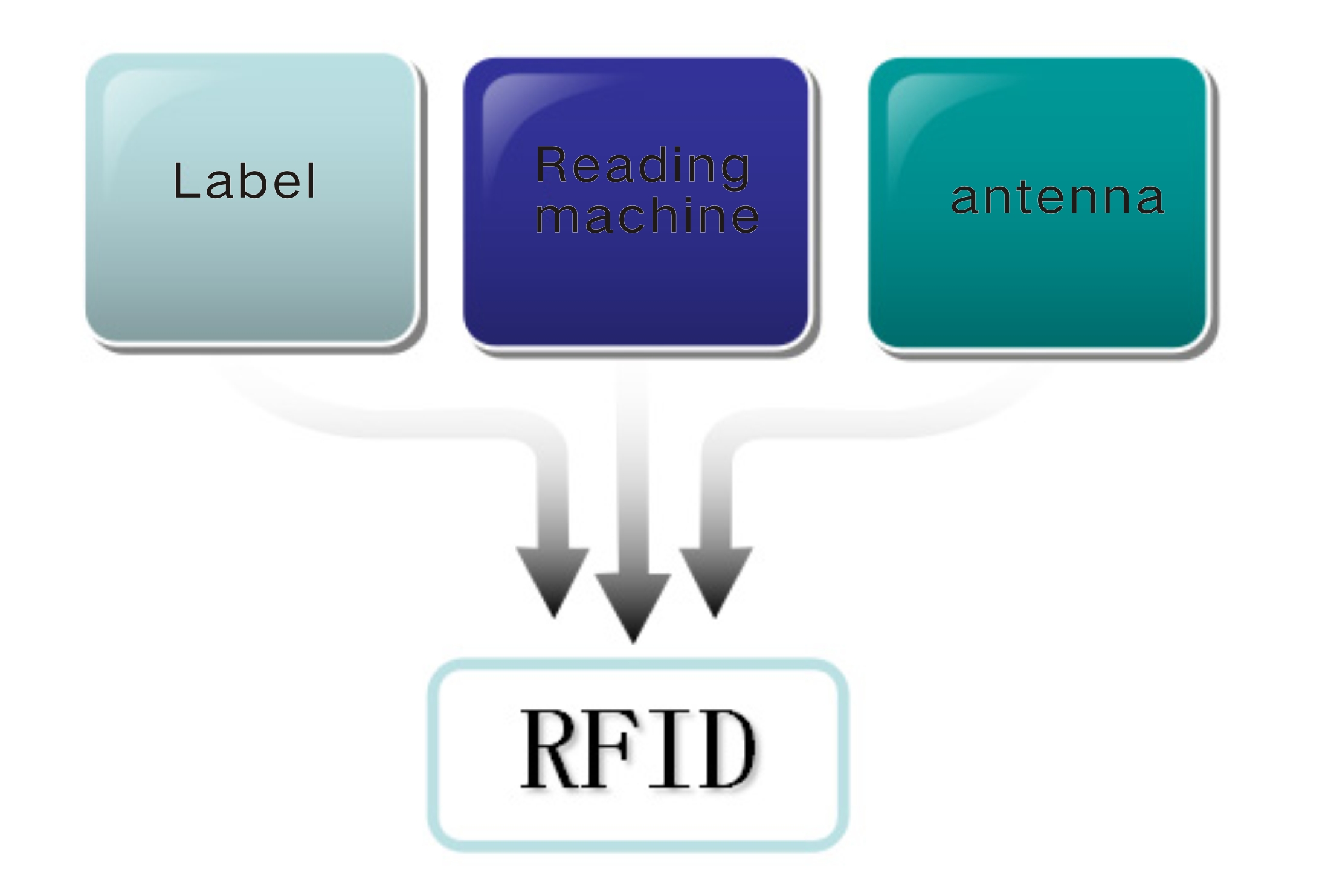

● What is a RFID?

RFID is an abbreviation for Radio Frequency Identification, or RFID, commonly known as electronic labels.

● What is the RFID technology?

RFID RF identification is a contactless automatic identification technology that automatically recognizes target objects and obtains relevant data through RF signals. The identification work is done without manual intervention and can work in a variety of harsh environments.RFID technology can recognize high-speed moving objects and can identify multiple labels simultaneously, fast and convenient to operate.

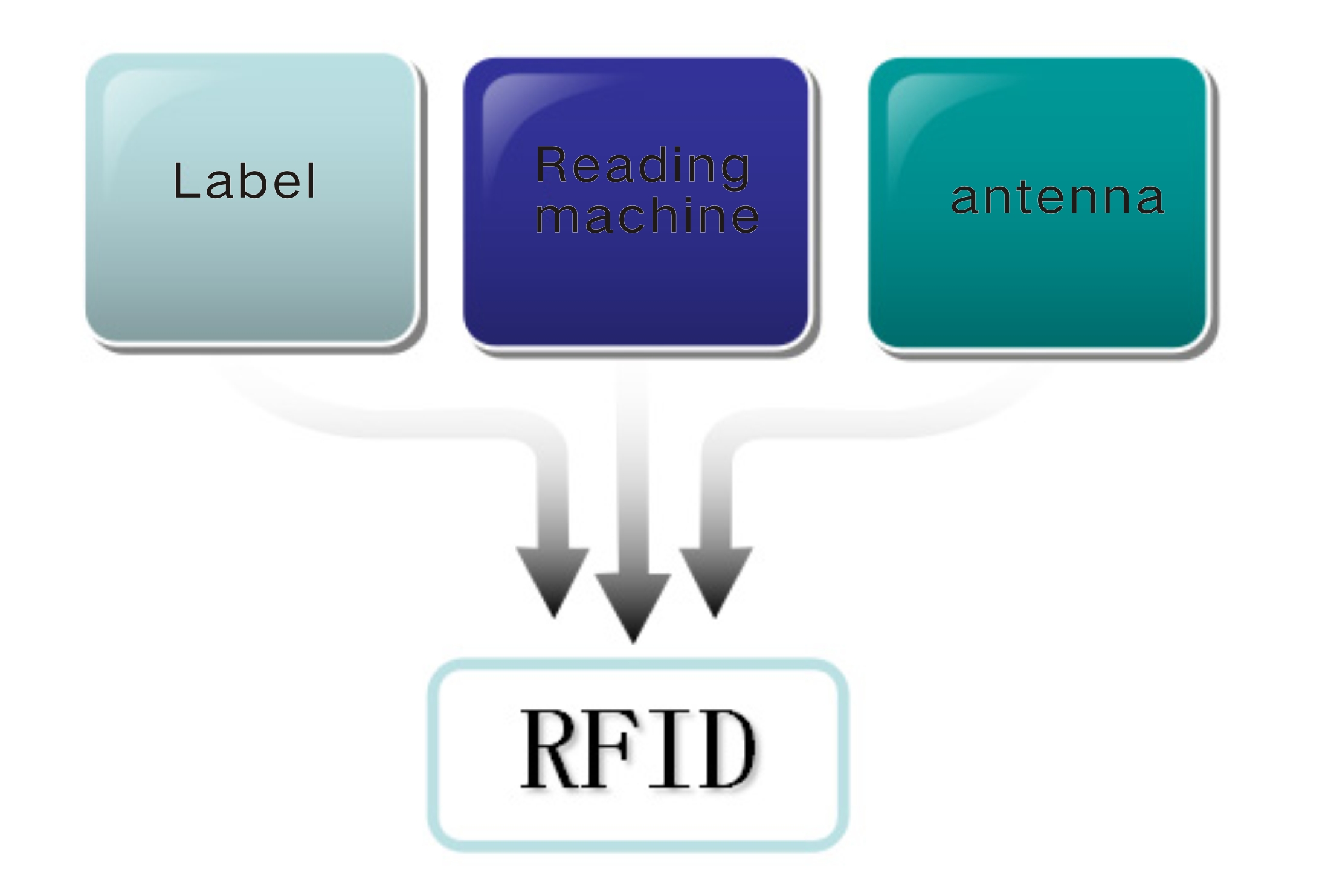

RFID is a simple wireless system with only two basic devices used to control, detect, and track objects.The system consists of an interrogator (or reader) and many transponders (or tags).

The basic component of the RFID

Overall design idea of the system

---------------------------------------------------------

● electronic Tray management based on RFID

●After the development of Industry No.1 project and the subsequent code typing project, a major bottleneck in the logistics operation of industrial warehouse code scanning enterprises.The implementation of RFID electronic tray management method can alleviate the bottleneck of industrial exit code scanning.We will support the industrial and commercial integrated transportation of finished cigarettes in the industry.

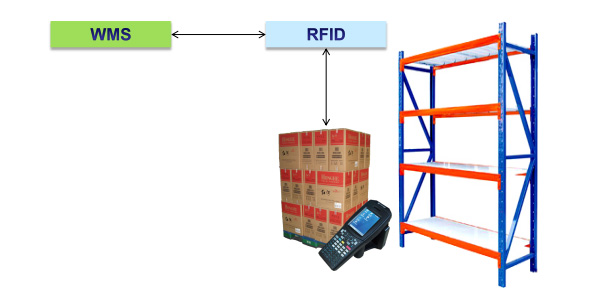

● is electronic location management based on RFID

●With the continuous development of tobacco logistics, as well as the development of industry No.1 project, code to bar and other projects, the requirements for logistics lean management are increasingly prominent, and the key in the logistics link, how to conduct more accurate and effective management of the location of goods, has naturally become the urgent requirement of tobacco circulation enterprises.

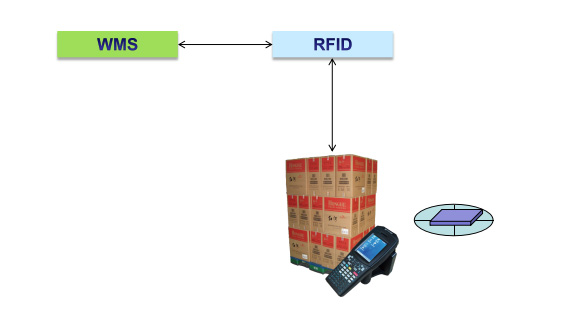

●with the application of RFID technology in the tobacco industry, cargo management can also be applied this new technology, based on RFID electronic cargo management can realize cigarette warehousing link tray up and down check, and electronic inventory function, not only convenient for the precise management of inventory, and improve the accuracy of warehousing operations.

●At the same time, the application of electronic cargo location management has also played a great auxiliary role in the management of the storage operation process. It can accurately record the operation information such as the starting and ending time of the operation process of each link, realize fine and trace management, and prepare for performance assessment.

Job operating system in the RFID library

--------------------------------------------------------------------------------------

●The project requires a WMS(digital storage management) system, so the operation operating system in the RFID library is a middleware between the background WMS system and the front-end hardware equipment.The WMS system completes the data exchange with the front-end hardware equipment through the operation operating system in the RFID library.

●The operation operating system in the RFID library contains functional modules of data communication, business logic, equipment control, data compression and data storage.Each functional module works in collaboration with the hardware equipment to complete the operation instructions issued by the WMS system.

Digital storage system for RFID technology

Traditional digital operation in the warehouse

-------------------------------------------------------------------------------

● static inventory management is mainly used

Manual operation mode of the ● job document

The real-time monitoring of ● storage operation is not in place, and the errors cannot be corrected in time

Warehouse operation

----------------------------------------

Out of warehouse operation

----------------------------------------

Trace adjustment

----------------------------------------

Position adjustment

----------------------------------------

Pick in the library

----------------------------------------

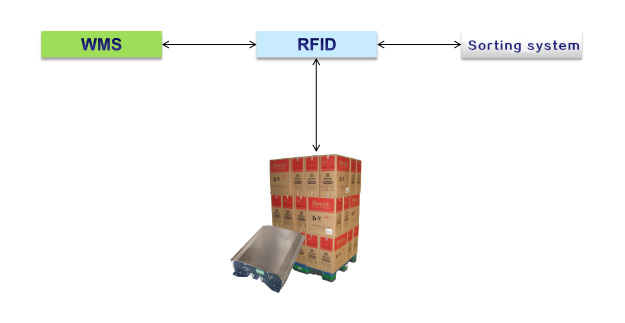

Prepare before sorting

----------------------------------------

After sorting, the film was wrapped

----------------------------------------

To be carried out and loaded

----------------------------------------

Inventory

----------------------------------------

System hardware introduction

----------------------------------------

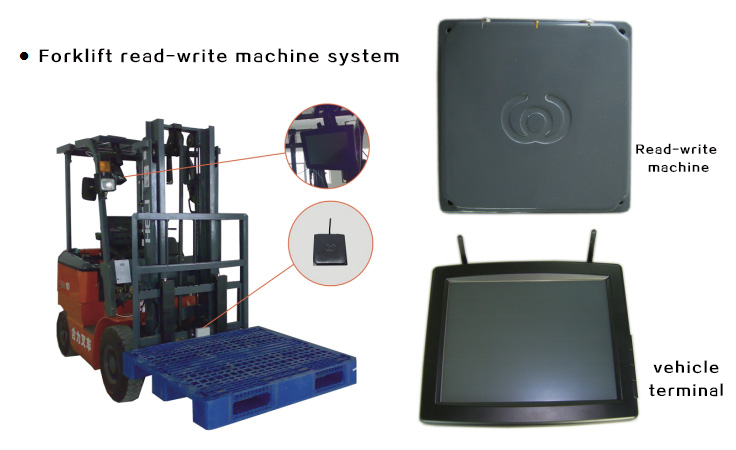

●forklift truck reader and writer system

Forklift performance parameters:

A real all-in-one reading and writer that looks like an antenna

Label protocol: ISO18000-6B

Stable read 6B tag distance above 2 m (non-pallet environment)

Wireless communication: Bluetooth (BLUETOOTH), reliable communication distance of 10 meters

Standby power consumption: 0.8W Working power consumption: 1.6W

Wide power supply voltage: DC is 4.5V-42V

Operating temperature: to be tested

Protection level: IP65

German ODU plug-lock connector: fast plug, high plug number,

Can be inserted blind, plug and pull force is small, the shell is easy to clean

The reader and writer has its voltage monitoring function to support battery power supply low voltage alarm

Fixed installation mode is flexible to accommodate most installation environments

Vehicle board terminal performance parameters:

Processor: Embedded VIA Eden 800 MHz CPU

Memory: 2 GB DDR 266 SDRAM is supported

Hard drive: 80G

Screen: a 12.1-inch touch LCD screen

Dimensions: (long x wide x high) 310 x 255 x 86 mm

Typical input voltage: 12V

Protection level of front and rear panel: IP65

Operating temperature: 0 ~ 45 ° C

Working humidity: 10% -95% (40 ° C)

Seismic resistance: 30G peak acceleration (duration 11 Ms)

EMC Certification: CE / FCC, Security Certification: UL

Operating system: Windows XP (by default)

Wireless network: Built-in Wi-Fi module, standard IEEE 802.11 a/b/g

Bluetooth: built-in Bluetooth (BLUETOOTH) module, effective distance of 10m, security authentication, data encryption

System hardware introduction

----------------------------------------

● Fixed Reader XCRF-500D

Performance parameters:

Dimensions: 229 × 312 × 92mm

Performance parameters:

Dimensions: 229 × 312 × 92mm

Weight: 3.4kg

Case material: Metal

Operating temperature: -10℃~+ 60℃

Storage temperature: -20℃~+ 70℃

Humidity: 95%

Working frequency band: 902~928MHz

Compliance with the criteria: ISO18000-6B

Digital interface: 4TTL input, 4TTL output

Data rate: 32 Kbps

Read and write distance: 0~7m(is related to antenna configuration)

Antenna interface: 1 N-type interface

Communication interface: RS 232,10M/100Mbps network interface and IO control interface

Power supply: 100-240 V AC /1A

Note: Six-port scheme, add IO control interface function

● handheld reader-writer XC-2900

Performance parameters:

Agreement agreement: ISO18000-6B/6C

Performance parameters:

Agreement agreement: ISO18000-6B/6C

Working frequency band: 902- -928MHZ

Read the label distance: 7M

Write the tag distance: 3.5M

Operating system: Wince CE5.0

Communication interface: USB Host,USB slave

Wireless communication interface: WIIF GPRS Bluetooth (optional)

Barcode: Industrial grade bar code module, supporting 1 D / 2 D, optional

Memory card: 1GMicro SD card (standard) with 2G support

Working mode: Trigger mode message mode

Continuous working hours: 10 hours for typical occasions

Standby time:>= for 15 days

Protection level: IP53

Power supply: DC 5V adapter

Supporting software: DEMO software, API, example program

● cargo location electronic label

Performance parameters:

Packaging material: The shell is composed of ABS+PC

Performance parameters:

Packaging material: The shell is composed of ABS+PC

Packaging method: the use of ultrasonic welding; waterproof and moisture-proof

Working mode: R/W(is readable and written)

Operating temperature: -25℃~70℃

Storage capacity: 64-bit serial number, 216 bytes of storage space

Operating Frequency: 860MHz~960MHz

Compliance with the criteria: ISO 18000-6B

Read-write distance: 0~10m (compatible with different antennas)

Adapt to the vehicle speed: 0~60km/h

Conflict prevention mechanism: suitable for multi-label reads

Installation method: double-sided glue, glass glue or screws can be used directly fixed to the object surface and can be used on the metal surface

Main function: the label used to identify metal items in the industrial environment, the shell is PC engineering plastic

Note: When using, keep the label polarization direction consistent with the reader daily polarization direction to obtain recognition performance

Typical applications: cargo location / shelf management, vehicle management, container management and other metal asset management, used for the identification of metal objects

Wide power supply voltage: DC is 4.5V-42V

Operating temperature: to be tested

Protection level: IP65

German ODU plug-lock connector: fast plug, high plug number,

Can be inserted blind, plug and pull force is small, the shell is easy to clean

The reader and writer has its voltage monitoring function to support battery power supply low voltage alarm

Fixed installation mode is flexible to accommodate most installation environments

Processor: Embedded VIA Eden 800 MHz CPU

Memory: 2 GB DDR 266 SDRAM is supported

Hard drive: 80G

Screen: a 12.1-inch touch LCD screen

Dimensions: (long x wide x high) 310 x 255 x 86 mm

Typical input voltage: 12V

Protection level of front and rear panel: IP65

Operating temperature: 0 ~ 45 ° C

Working humidity: 10% -95% (40 ° C)

Seismic resistance: 30G peak acceleration (duration 11 Ms)

EMC Certification: CE / FCC, Security Certification: UL

Operating system: Windows XP (by default)

Wireless network: Built-in Wi-Fi module, standard IEEE 802.11 a/b/g

Bluetooth: built-in Bluetooth (BLUETOOTH) module, effective distance of 10m, security authentication, data encryption

Weight: 3.4kg

Case material: Metal

Operating temperature: -10℃~+ 60℃

Storage temperature: -20℃~+ 70℃

Humidity: 95%

Working frequency band: 902~928MHz

Compliance with the criteria: ISO18000-6B

Digital interface: 4TTL input, 4TTL output

Data rate: 32 Kbps

Read and write distance: 0~7m(is related to antenna configuration)

Antenna interface: 1 N-type interface

Communication interface: RS 232,10M/100Mbps network interface and IO control interface

Power supply: 100-240 V AC /1A

Note: Six-port scheme, add IO control interface function

Working frequency band: 902- -928MHZ

Read the label distance: 7M

Write the tag distance: 3.5M

Operating system: Wince CE5.0

Communication interface: USB Host,USB slave

Wireless communication interface: WIIF GPRS Bluetooth (optional)

Barcode: Industrial grade bar code module, supporting 1 D / 2 D, optional

Memory card: 1GMicro SD card (standard) with 2G support

Working mode: Trigger mode message mode

Continuous working hours: 10 hours for typical occasions

Standby time:>= for 15 days

Protection level: IP53

Power supply: DC 5V adapter

Supporting software: DEMO software, API, example program

Packaging method: the use of ultrasonic welding; waterproof and moisture-proof

Working mode: R/W(is readable and written)

Operating temperature: -25℃~70℃

Storage capacity: 64-bit serial number, 216 bytes of storage space

Operating Frequency: 860MHz~960MHz

Compliance with the criteria: ISO 18000-6B

Read-write distance: 0~10m (compatible with different antennas)

Adapt to the vehicle speed: 0~60km/h

Conflict prevention mechanism: suitable for multi-label reads

Installation method: double-sided glue, glass glue or screws can be used directly fixed to the object surface and can be used on the metal surface

Main function: the label used to identify metal items in the industrial environment, the shell is PC engineering plastic

Note: When using, keep the label polarization direction consistent with the reader daily polarization direction to obtain recognition performance

Typical applications: cargo location / shelf management, vehicle management, container management and other metal asset management, used for the identification of metal objects

This solution uses RFID technology to achieve precise control of the operation process, thereby ensuring the correct implementation of the operation task.

Basically eliminate the errors in the stacking operation of the cargo space, so that the correct rate of the cargo space stacking has the level of the automatic warehouse. Therefore, the storage space and the pallet

"Inventory mode" can realize the transition from "bit-by-bit inventory" to "district sampling inventory", which innovates the inventory mode and reduces the workload of inventory.

Improve inventory efficiency.